Creator studio

what is DTG printing?

DTG or Direct-to-Garment printing is a method of printing images or graphics onto a textile. It’s a production technique that began in the US in 1996 and is based on a patented innovation by Matthew Rhome. When it comes to on demand merch, DTG has emerged as the industry go-to and for good reason – it produces exceptional merch.

what’s the difference between DTG and other printing?

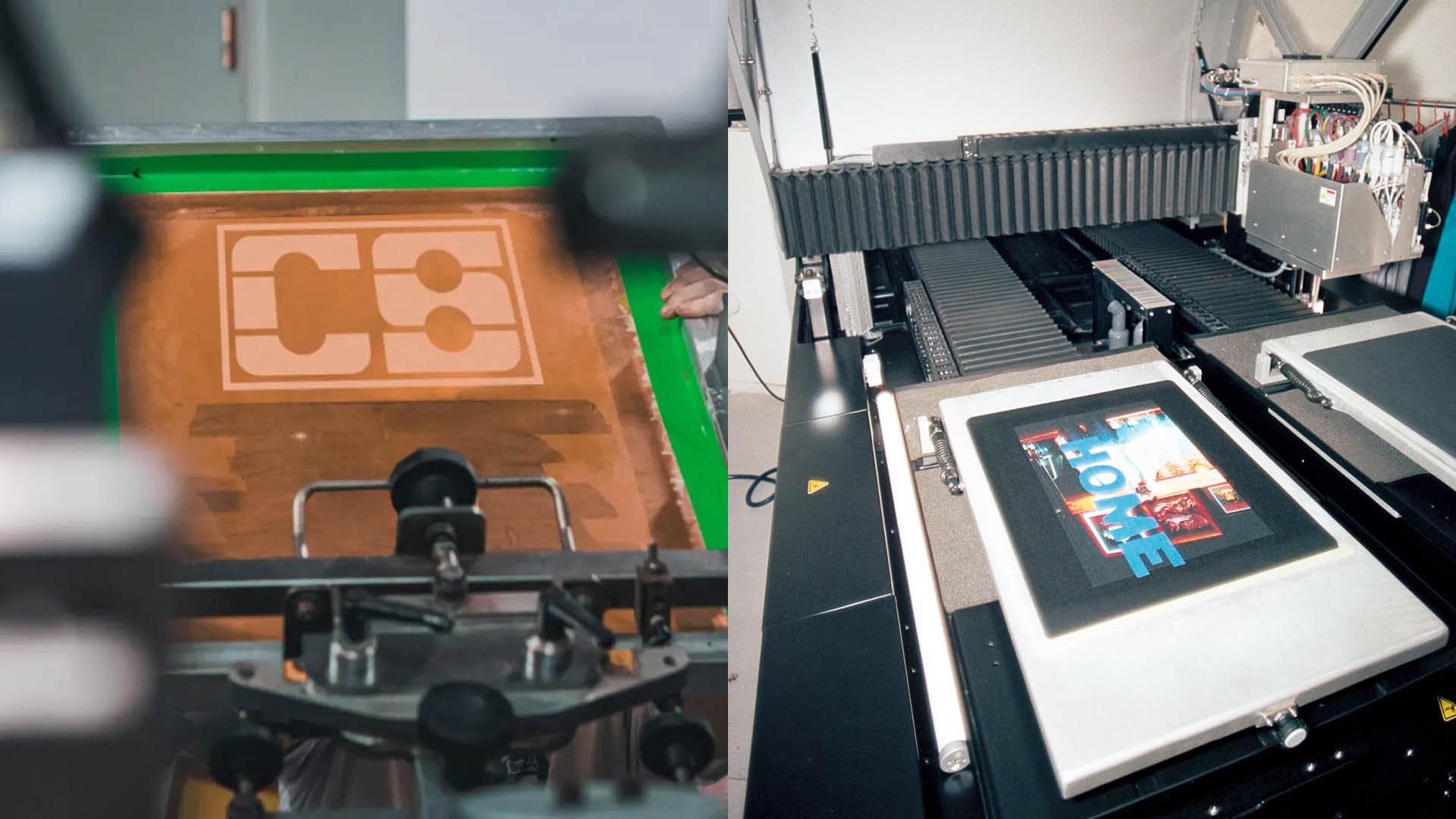

Unlike other kinds of printing, like screen printing, heat transfer or dye sublimation, DTG uses a big printer with special inks that print straight onto a garment. The fibres of the garment soak up the ink, rather than it nestling on the surface. As a result, the printed image is far more resilient against cracking.

how does DTG work as part of merch on demand?

When one of your fans buys one of your products, our DTG flow kicks into action. The Creator Studio tech locates the nearest production hub to where your fan is based and initiates a print run of exactly the quantity required.

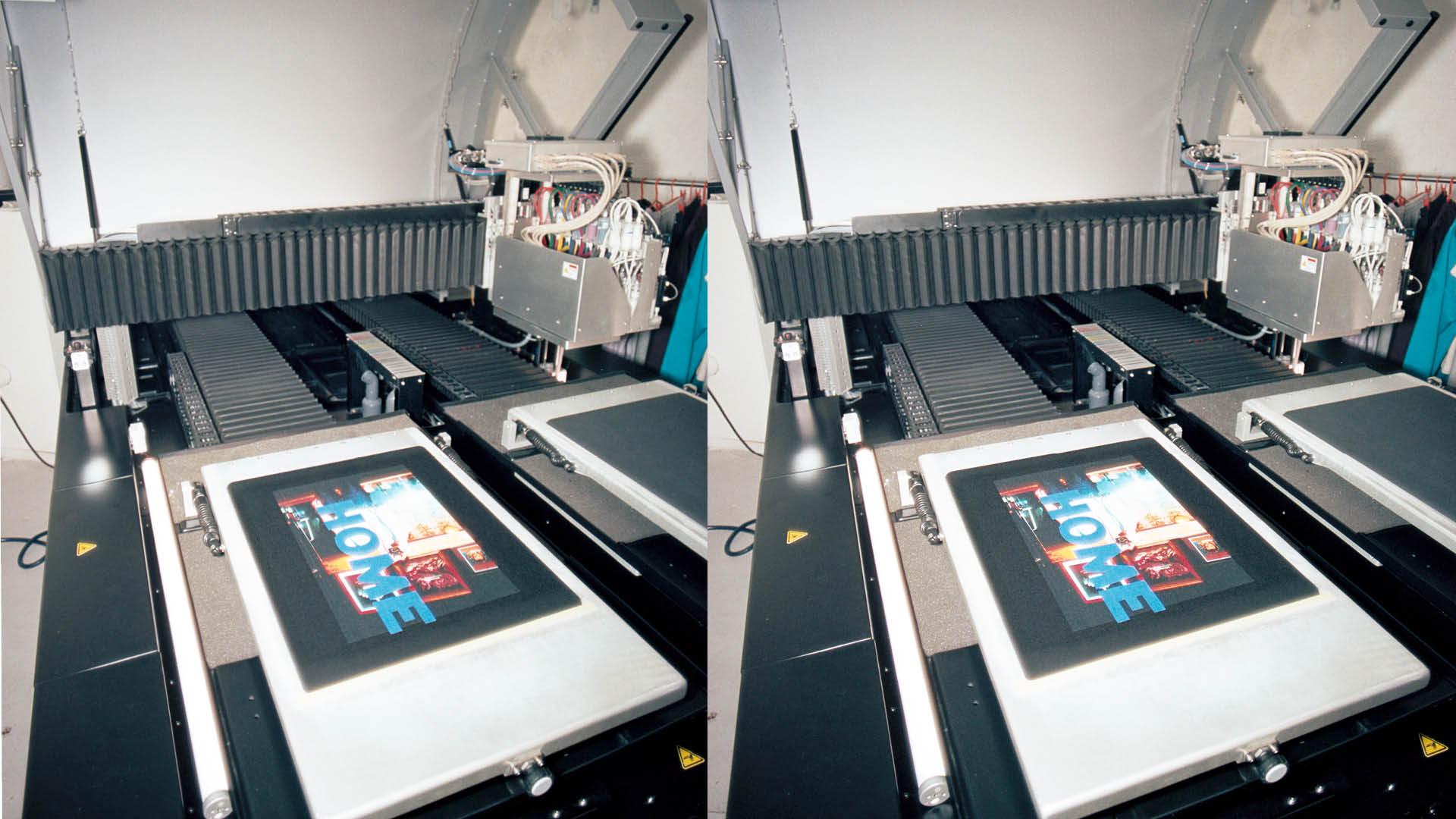

All our hubs use one type of machine, by Kornit, to ensure consistent reproduction wherever you are. Each hub also exclusively only prints Creator Studio merch on our in-house merch apparel by our label True Blanks. For even better consistency and reproduction, Creator Studio has its own ink mixes that are optimised for each different type of True Blanks garment and colourway. Small points of differentiation that add up to a considerable difference in the quality of the outcome.

stages of DTG printing

- Typically, the garment will be heat pressed to get rid of any moisture locked in the fibres and flatten out the fibres.

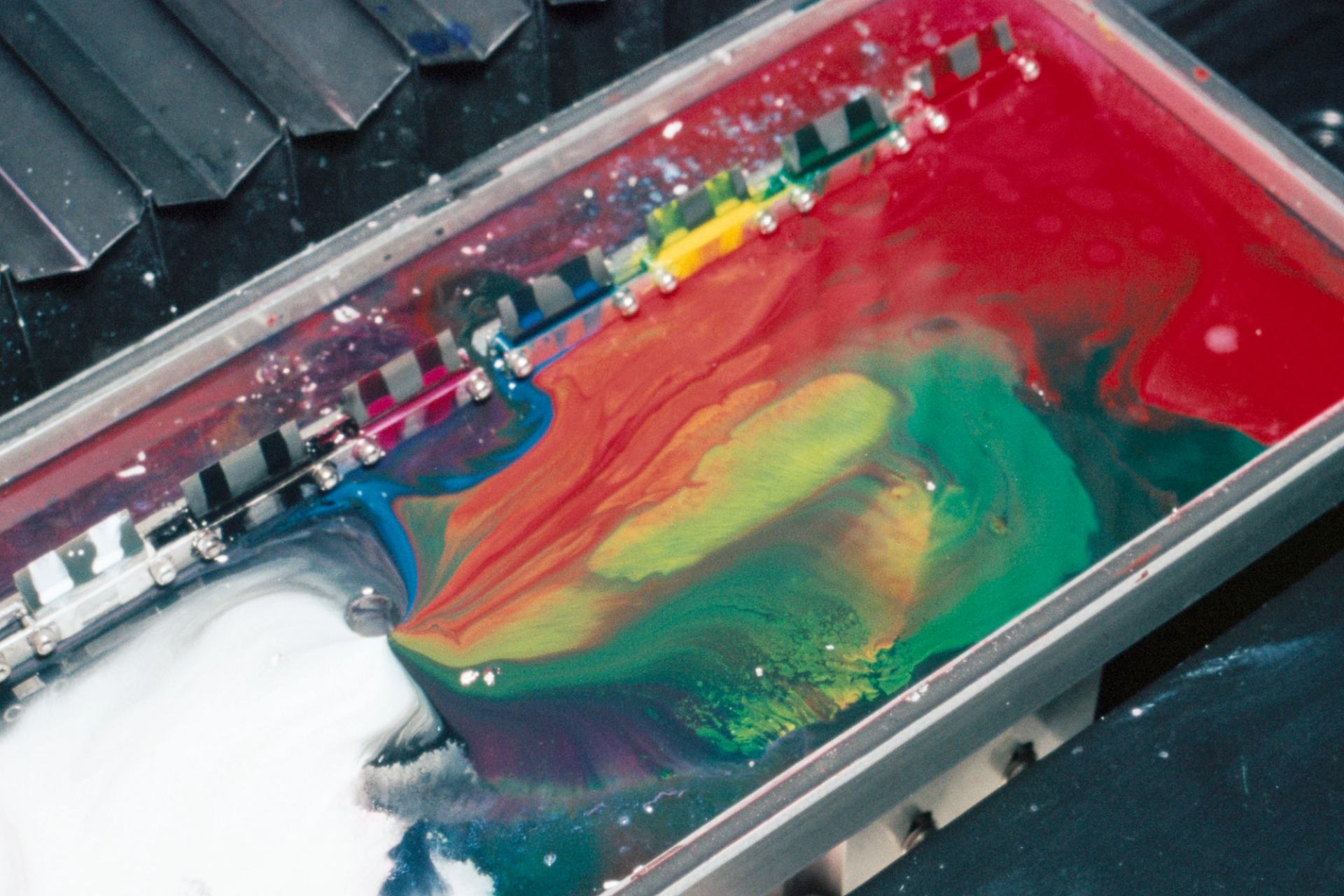

- Pre-coating/fixation agent is then applied. This is a water-based agent that’s sprayed lightly over the garment’s print area before printing with the pigment. It’s what used to make your new printed apparel smell slightly of vinegar. Today, DTG printers are using a revised formula with less odour.

- Depending on the colour of the blank, the printer may apply a white under base to counterbalance the garment’s dye and the effect it may have on the coloured inks used to print your design. If your artwork is being printed on white, it’s often not needed. In some cases, this white under base will be applied right before the garment has the rest of the colours added.

- The garment will be heated to affix the pre-coating to the garment.

- The piece of apparel will then be loaded into the machine and the print area positioned on a plate to hold it in place.

- Your artwork print file will be loaded into the print machine, which will adjust to the correct setting for the garment.

- Printing will begin.

- Finally, the merch garment will be removed gently and placed onto a heat press. It can be done manually but most of the time your garment will head off on a conveyor belt to pass through a dryer that fixes and cures the ink.

- After a final quality inspection, your merch will be folded, packaged and sent to your eager fans.

What Is Print On Demand

Our simple breakdown of print on demand as a business model, and explainer on why it's changing how we make fashion and enable creativity.

Read more

How To Start A Print On Demand Business

Want to start a print on demand business? Here's Creator Studio's simple guide to getting up and running in the most dynamic and creative industry out there.

Read more

How To Create And Sell Merchandise Online

The Creator Studio guide to creating and selling on demand merchandise online.

Read more

How To Create A Marketing Calendar

Everything you need to know about create a marketing calendar with our guide.

Read more

How To Create A Clothing Collection

Everything you need to know about starting your own clothing collection from scratch, using print on demand to mazimise your success while keep costs to basically zero!

Read more

How To Sell Merch On Spotify

Read our guide and learn how to link Shopify to Spotify. A win-win situation for a record label, band, producer or artist!

Read more

Screen Printing vs DTG

Read our guide about the difference between Screen printing and DTG (direct-to-garment) printing!

Read more

© Creator Studio 2025 - Part of H&M Group

106 38 Stockholm, Sweden